Shenzhen-based Bambu Lab has unveiled its new H2D 3D Printer, a hotly anticipated system that has been the subject of intense online speculation over recent weeks.

The H2D is an all-in-one desktop manufacturing unit. It offers Bambu Lab’s largest ever build volume, 350 x 320 x 325 mm, along with two new AMS systems with integrated filament drying. Dual-nozzle extrusion and servo motors enhance accuracy, while 1000 mm/s toolhead speed and 20,000 mm/s² acceleration boost productivity. The H2D’s 65°C heated chamber and 350°C hotend allow users to 3D print advanced filaments, including carbon and glass fiber-reinforced materials.

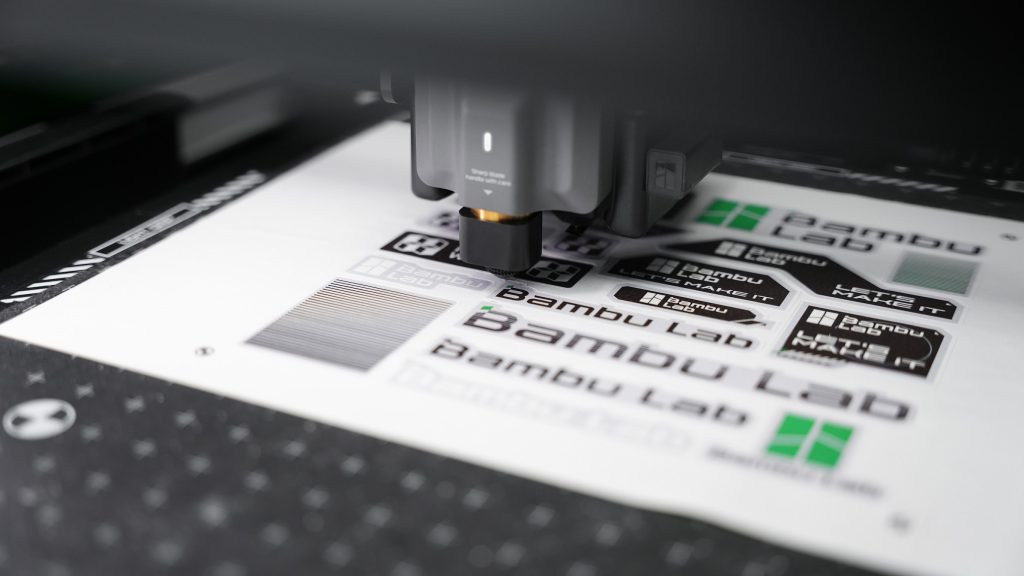

Perhaps most intriguing, however, is the inclusion of laser cutting and engraving, digital cutting, and pen drawing capabilities. The H2D is available with two different laser power options. The standard 10W laser can cut up to 5 mm of Basswood Plywood, while the 40W laser can tackle materials up to 15 mm thick. Bambu Lab has also entered the digital cutting (or vinyl cutting) market with the H2D. Its blades, with a maximum cutting thickness of 0.5 mm, allow users to cut designs in materials like paper, vinyl, and leather.

Bambu Lab claims its new offering “is not a conventional 3D printer with added accessories,” but “an entirely new category of product.” The company asserts that the all-in-one H2D does not compromise quality for versatility, and “excels at each capability it offers,” pre-empting concerns often associated with jack-of-all-trade systems.

“The H2D represents the culmination of our vision to fundamentally transform how designers, engineers, and makers approach personal manufacturing,” explained Bambu Lab’s CEO, Dr. Ye Tao. “We’ve built the H2D with the goal to excel at every capability it offers, eliminating the traditional ‘jack of all trades, master of none’ compromise that has plagued this product category.”

Pricing for the Bambu Lab H2D 3D printer lineup is between $1,899 USD and $3,499 USD, depending on the options selection. The H2D is available in four configurations designed to meet different user requirements. These include the $1,899 H2D, $2,199 H2D AMS Combo, $2,799 H2D Laser Full Combo (10W), and $3,499 H2D Laser Full Combo (40W).

The H2D AMS Combo is in stock and ready to order now, while the basic H2D model will be available in June 2025. Both H2D Laser Full Combo can be pre-ordered now, with shipping expected to commence at the end of April 2025. More information is available via the official Bambu Lab online store.

The Bambu Lab H2D Laser Full Combo in a workshop. Image via Bambu Lab.

The Bambu Lab H2D Laser Full Combo in a workshop. Image via Bambu Lab.

Bambu Lab H2D Pricing and Availability

Model Items IncludedPrice (USD)AvailabilityH2DBuild plate, spool holder, accessory box$1,899Available starting June 2025H2D AMS ComboAMS 2 Pro, build plate, spool holder, accessory box$2,199In stock and ready to orderH2D Laser Full Combo (10W)AMS 2 Pro, build plate, spool holder, accessory box, 10W laser module, cutting module, laser platform, cutting platform, emergency stop button$2,799Available for pre-order, shipping end of AprilH2D Laser Full Combo (40W)AMS 2 Pro, build plate, spool holder, accessory box, 40W laser module, cutting module, laser platform, cutting platform, emergency stop button$3,499Available for pre-order, shipping end of April

(From left to right) The Bambu Lab H2D’s 10W laser, dual nozzle printhead, cutting module, and pen holder. Image via Bambu Lab.

(From left to right) The Bambu Lab H2D’s 10W laser, dual nozzle printhead, cutting module, and pen holder. Image via Bambu Lab.

Introducing the new Bambu Lab H2D 3D printer

Bambu Lab offers its H2D and H2D AMS Combo for users who only require FDM 3D printing without additional cutting and engraving functionalities. A 325 x 320 x 325 mm³ build volume is available during single-nozzle 3D printing, while 300 x 320 x 325 mm³ supports dual-nozzle fabrication. The H2D’s total 3D printing volume for two nozzles comes to 350 x 320 x 325 mm³.

The new FDM 3D printer’s dual hardened steel nozzles mark a shift from Bambu Lab’s previous single-extruder, multi-material 3D printers. Its new architecture will save time and reduce material waste by cutting filament-purging requirements. Additionally, one nozzle can be dedicated to support material, while the other handles the primary 3D printing filament. This unlocks easier support removal, fewer post-processing steps, and cleaner parts.

Bambu Lab’s H2D leverages the company’s proprietary DynaSense Extruder with a Permanent Magnet Synchronous Motor (PMSM) servo architecture. The system integrates a Bambu-designed permanent magnet brushless servo motor offering precise torque, speed, and position control over the printhead. It also boasts live extrusion pressure monitoring, automatic partial nozzle clog detection, and filament grinding prevention to enhance quality and reliability during high-speed 3D printing.

The H2D’s Eddy Current Nozzle Calibration technology further enhances extrusion performance. Bambu Lab’s proprietary system automatically manages X/Y offset calibration for the dual nozzles, meaning users do not have to conduct the manual calibration steps required by similar dual-nozzle systems.

Another key feature is the addition of an “AI-backed,” macro lens nozzle camera. This updated visual monitoring system can detect material build-up, filament issues, and common 3D printing failures like nozzle clumping, air printing, and spaghetti. Material flow monitoring is further provided by the 3D printer’s SOTA filament control system. 15 sensors track filament as it travels between the AMS and nozzles, continuously monitoring feeding velocity, tension, filament tip location, extruder thermal environment, and dynamic extrusion pressure.

An integrated vision-assisted encoder system is also critical to the H2D’s operation. This reportedly delivers 50µm motion accuracy across the entire build volume. Bambu Lab claims that this level of precision has previously only been available on “industrial machines,” facilitating the production of “perfectly dimensioned parts.”

Inside the Bambu Lab H2D’s dual nozzle printhead. Image via Bambu Lab.

Inside the Bambu Lab H2D’s dual nozzle printhead. Image via Bambu Lab.

Bambu Lab has also announced two new AMS systems for the H2D. AMS 2 Pro combines filament drying functionality with electromagnetic vents. These automatically toggle between drying mode and storage, ensuring materials remain moisture-free up until the print job. On the other hand, Bambu’s new AMS HT is focused primarily on engineering-grade applications. It can dry material at up to 85°C and features a Filament Bypass Path to reduce resistance for rigid, fiber-reinforced filaments and soft TPU.

This new AMS 2 Pro comes standard with the Bambu Lab’s H2D AMS Combo and H2D Laser Full Combo configurations. However, it is not featured in the basic H2D model, which is compatible with Bambu Lab’s first-generation AMS.

The Bambu Lab H2D’s laser capabilities

Bambu Lab offers two H2D Laser Full Combo models boasting integrated cutting, engraving, and drawing capabilities. The 10W laser configuration serves makers “who want to go beyond 3D printing and integrate additional manufacturing capabilities.” Bambu calls the H2D 40W option its “most comprehensive configuration for maximum manufacturing versatility.”

Bambu’s Live Spatial Alignment technology manages tool-changing actions, ensuring “seamless transitions between tools.” The H2D’s toolhead camera works with a BirdsEye camera to achieve 0.3 mm positioning accuracy, allowing users to integrate multiple functions into their manufacturing projects.

The H2D employs a Semiconductor Laser during laser cutting and engraving operations. For the latter, a 455 nm ± 5 nm Blue Light laser is used to unlock maximum engraving speeds of 400 mm/s for the 10W offering and 1000 mm/s for the 40W system. The 10W engraving area is 310 mm x 270 mm, while the H2D Laser Full Combo (40W) can engrave 310 mm x 250 mm.

Bambu’s 10W and 40W laser modules work with a wide range of materials, including wood, rubber, sheet metal, leather, dark acrylic, and stone. An integrated air assist pump and vision-based alignment system enhance laser performance. For safety, each system includes laser-safe windows, five flame sensors, AI-powered fire detection, and emergency stop buttons.

Laser engraving with the Bambu Lab H2D. Image via Bambu Lab.

Laser engraving with the Bambu Lab H2D. Image via Bambu Lab.

Both all-in-one manufacturing units include a digital cutting module with a 45° x 0.35 mm blade, applying between 50 gf and 600 gf of pressure. They come with LightGrip and StrongGrip Cutting Mats, supporting a maximum cutting area of 300 x 285 mm². Additionally, the H2D offers pen drawing capabilities, providing extra design flexibility within a 300 x 255 mm² drawing area.

These tools are compatible with paper, vinyl, and leather materials, supporting Bitmap and Vector Images. Bambu claims they enable users to create vinyl cuts, custom stickers, and technical drawings “with the same precision as dedicated machines.”

Technical specifications of the Bambu Lab H2D 3D Printer

ItemSpecification 3D Printing TechnologyFused Deposition ModelingBodyBuild Volume (W*D*H)Single Nozzle Printing: 325*320*325 mm³Dual Nozzle Printing: 300*320*325 mm³

Total Volume for Two Nozzles: 350*320*325 mm³

Chassis & ShellAluminum, Steel, Plastic and GlassLaser Safety WindowsEquipped on Laser Edition, normal H2D can upgrade through Laser Upgrade KitAir Assist PumpEquipped on Laser Edition, normal H2D can upgrade through Laser Upgrade KitPhysical DimensionsPhysical Dimensions492*514*626 mm³Net Weight 31 kgToolheadHotendAll MetalExtruder GearHardened SteelNozzleHardened SteelMax Nozzle Temperature350 °CIncluded Nozzle Diameter0.4 mmSupported Nozzle Diameter0.2 mm, 0.4 mm, 0.6 mm, 0.8 mmFilament Diameter1.75 mmExtruder MotorBambu Lab High-precision Permanent Magnet Synchronous Motor (PMSM)HeatbedSupported Build Plate TypeTextured PEI plate, Smooth PEI PlateMax Heat Bed Temperature120℃3D Print SpeedMax Speed of Toolhead1000 mm/sMax Acceleration of Toolhead20,000 mm/s²Max Flow for Hoten d(Standard Flow Hotend)40 mm³/s (Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280°C printing temperature)Max Flow for Hotend(Optional High-Flow Hotend)65 mm³/s (Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280°C printing temperature)Chamber Temperature ControlActive Chamber HeatingSupportedMax Temperature65°CAir PurificationPre-filter GradeG3HEPA Filter GradeH12Activated Carbon Filter TypeGranulated Coconut ShellSupported Filament TypePLA, PETG, TPU, PVA, BV OH, ABS, ASA, PC, PA, PET, Carbon/Glass Fiber Reinforced PLA,PETG, PA, PET, PC, ABS, ASA, PPA-CF/GF, PPS, PPS -CF /GFSensorLive View CameraBuilt-in; 1920*1080Nozzle CameraBuilt-in; 1920*1080BirdsEye CameraBuilt-in; 3264*24 48 (Equipped with Laser Edition)Toolhead CameraBuilt-in; 1920*1080Electrical RequirementsVoltage100-120 VAC / 200-240 VAC, 50/60 HzMax Power2200 W@220 V / 1320 W@110 VAverage Power1050 W@220 V / 1050 W@110 VElectronicsTouchscreen5-inch 720*1280 TouchscreenStorageBuilt-in 8 GB EMMC and USB PortControl InterfaceTouchscreen, mobile App, PC AppNeural Processing Unit2 TOPSSoftware Slicer & SoftwareBambu Studio, Bambu Suite, Bambu HandySupports third-party slicers that export standard G-code, such as Super Slicer, PrusaSlicer, and Cura, but certain advancedfeatures may not be supportedSupported Operating SystemMacOS, Windows10W & 40W Laser ModuleLaser TypeSemiconductor LaserLaser WavelengthEngraving Laser: 455 nm ± 5 nm Blue LightHeight Measuring Laser: 850 nm ± 5 nm Infrared LightLaser Power10 W ± 1 W; 40 W ± 2 WLaser Spot Dimension10W: 0.03 mm*0.14 mm; 40W: 0.14 mm*0. 2mmWorking Temperature0°C–35 °CMax Engraving Speed10W: 400 mm/s; 40W: 1000 mm/sMax Cutting Thickness10W: 5 mm; 40W: 15mm (Basswood Plywood)Engraving Area10W : 310 mm * 270 mm; 40W : 310 mm * 250 mmXY Positioning Accuracy< 0 . 3 mmZ Height Measuring MethodMicro LidarZ Height Measuring Accuracy± 0.1 mmVentilation Pipe Adapter Outer Diameter100 mmSupported Material TypeWood, rubber, metal sheet, leather, dark acrylic, stone, and moreCutting ModuleCutting Area300*285 mm²Drawing Area300*255 mm²Supported Pen Diameter10.5 mm-12.5 mmCutting Mat TypeLightGrip and StrongGrip Cutting MatsBlade Type45°*0.35 mmBlade Pressure Range50 gf-600 gfMax Cutting Thickness0.5 mmSupported Image TypeBitmap and Vector ImagesSupported Material TypePaper, vinyl, leather, and more

Who won the 2024 3D Printing Industry Awards?

Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.

You can also follow us on LinkedIn, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the Bambu Lab H2D Laser Full Combo with AMS 2 Pro and AMS HT. Image via Bambu Lab.